V- LITE BLOCKS

Autoclaved Aerated Concrete (AAC)

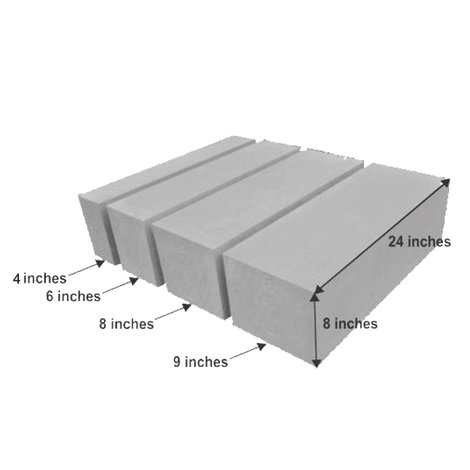

| Block Sizes | Weight of Block (approx) | Blocks in 1 CBM. |

|---|---|---|

| 600x200x200mm | 16 to 17 Kgs. | 42 Nos. |

| 600x200x150mm | 12 to 13 Kgs | 55 Nos. |

| 600x200x125mm | 10 to 11 Kgs. | 67 Nos. |

| 600x200x100mm | 8 to 9 Kgs. | 83 Nos. |

| 600x200x75mm | 6 to 7 kgs. | 111 Nos. |

Advantages

Light Weight

Eco Friendly

Fast & Time Saving

Acoustic Performance

Pest Resistant

Earthquake Resistant

Fire Resistant

Thermal Insulation

Energy Saving

Cost Effective

Easy Handling

Minimum Breakage

No Curing Required

| Technical Details | Value |

|---|---|

| State | Solid |

| Colour | Grey |

| Sizes | 600 x 200 x (100-300) mm |

| Size Tolerance | + / - 3mm |

| Compressive Strength | > 3 N/mm2 |

| Dry Density | 550 -650 kg/m3 (Depending on grade of AAC block) |

| Fire Resistance | 4 to 6 Hours depends upon thickness of wall |

| Sound Reduction | upto 45 db |

| Dry Shrinkage | 0.04% of the size of the block |

| Thermal Conductivity w/(km) | 0.25 w/mk |

| IS CODE | 2185 Part-3 |

Thickness of Joints :-

- 2-3 mm thin bed while using Jointing Mortar, against 10-12 mm thick mortar in conventional mortar.

Application Procedure Of AAC Blocks

Preparation of the Substrate: The substrate or the concrete surface on which the AAC blocks will be laid should be cleaned, levelled, and compacted to ensure a stable base for the blocks.

Installation of Lateral Support: Lateral support should be installed around the perimeter of the wall to provide stability and support for the AAC blocks.

Mixing of Mortar: A suitable mortar mix should be prepared for the jointing of the AAC blocks. Preferably Insta BJM to be mixed as per mixing procedure and water to be added.

Laying of AAC Blocks: Blocks should be laid on the substrate and jointed with the mortar from corners & working towards center of the wall. The blocks should be laid vertically, level and plumb, with consistent joint widths and depths.

Cutting of AAC Blocks: If necessary, AAC blocks can be cut to fit specific dimensions using a masonary saw or other appropriate cutting tools.

Reinforcement: If required, reinforcement can be added to the AAC blocks using steel bars or mesh to provide additional strength and stability to the wall.

Application of Finishing Coat: Once the AAC blocks have been installed, a finishing coat of paint or plaster can be applied to provide an attractive and durable surface finish.

Types of V Lite Blocks

| Density of block in oven dry condition (kg/CBM) | Comp. Strength (N/mm2) for Grade I | Comp. Strength (N/mm2) for Grade II | Area of Application |

|---|---|---|---|

| 451 to 550 | 2 | 1.5 | Non - load bearing Walls, Partitions, Insulation, Landscaping. |

| 551 to 650 | 4 | 3 | Load-bearing walls, partitions and Foundations. |

| 651 to 750 | 5 | 4 | Load-bearing walls, partitions and Foundations. |

Area of Application

Block Jointing Mortar is recomended for fixing of AAC Block

- Residential

- Commercial and Industrial Buildings

- Warehouses

- Hospitals

- Hotels

- Amusement Parks

- Auditorium

- Theatres

- Firewalls

- Shaftwalls

- Power Plant

- etc

- Residential

- Commercial and Industrial Buildings

- Warehouses

- Hospitals

- Hotels

- Amusement Parks

- Auditorium

- Theatres

- Firewalls

- Shaftwalls

- Power Plant

- etc

Do's

- 1. Proper site preparation: Ensure that the construction site is level, clean, and free of debris before laying the AAC blocks.

- 2. Proper storage: Store AAC blocks in a dry, protected area to prevent damage and ensure that they are in good condition for use.

- 3. Use the right tools: Use the right tools and equipment for cutting and shaping the AAC blocks, including specialized saws and equipment designed specifically for cutting and shaping AAC blocks.

- 4. Proper installation: Follow the manufacturer’s guidelines for proper installation, including proper spacing and alignment of the blocks, and the use of appropriate mortar and grout.

- 5. Use adequate support: Ensure that the AAC blocks are adequately supported during the installation process, especially when building load-bearing walls.

- 6. Seal the blocks: Seal the AAC blocks with a suitable mortar to prevent moisture from penetrating the surface and causing damage over time.

- 7. Use the appropriate grade: Choose the appropriate grade of AAC blocks for the construction project, based on the load-bearing requirements and design specifications.

- 8. Hire skilled labour : Hire skilled and experienced labour for the installation process to ensure that the AAC blocks are installed correctly.

Don'ts

- 1. Don’t expose to moisture: Avoid exposing AAC blocks to moisture or damp conditions, as this can cause damage and weaken the structure over time.

- 2. Don’t use the wrong tools: Avoid using the wrong tools or equipment for cutting and shaping the AAC blocks, as this can cause damage and negatively impact the quality of the construction project.

- 3. Don’t use the wrong mortar: Avoid using the wrong type of mortar or grout for installing the AAC blocks, as this can affect the strength and durability of the structure.

- 4. Don’t overload the blocks: Avoid overloading the AAC blocks, as this can cause damage and increase the risk of failure.

- 5. Don’t skimp on support: Avoid skimping on support during the installation process, as this can affect the stability and safety of the structure.

- 6. Don’t neglect proper alignment: Avoid neglecting proper alignment and spacing of the AAC blocks during the installation process, as this can negatively impact the strength and stability of the structure.

- 7. Don’t use damaged blocks: Avoid using damaged or broken AAC blocks in the construction project, as this can weaken the structure and reduce its overall quality.

- 8. Don’t ignore safety standards: Avoid ignoring safety standards and guidelines when using AAC blocks for construction, as this can put workers and the public at risk and negatively impact the quality of the construction project.

Usage of AAC Blocks :-

- 1. Load-bearing walls: AAC blocks are suitable for building load-bearing walls, due to their strength and durability.

- 2. Partitions: AAC blocks are often used to build partitions and separating walls.

- 3. Fire-resistant construction: AAC blocks are fire-resistant and do not emit toxic gases, making them a suitable choice for use in fire-resistant construction projects.

- 4. Insulation: The cellular structure of AAC blocks provides excellent insulation properties, making them a suitable choice for use in energy-efficient construction projects.

- 5. Masonary: AAC blocks can be used as a substitute for traditional masonary materials, such as bricks and concrete blocks.

- 6. Landscaping: AAC blocks can also be used in landscaping projects and garden walls.

Safety Measures

Safety Measures While Fixing AAC Blocks:

- 1. Personal protective equipment: Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, safety shows and a dust mask, to protect yourself from dust, debris, and flying particles.

- 2. Use the right tools: Use the right cutting tools, such as a diamond blade, to cut AAC blocks. Make sure the tool is in good condition, and always follow the manufacturer's instructions for safe use.

- 3. Secure the blocks: AAC blocks can be heavy and may shift during cutting or installation. Make sure the blocks are securely held in place before cutting or installing them to prevent them from falling or tipping over.

- 4. Work in a well-ventilated area: Cutting AAC blocks can create a lot of dust, which can be harmful if inhaled. Work in a well-ventilated area or use a dust extraction system to keep the air clean and reduce the risk of respiratory problems.

- 5. Keep the work area clean: Keep the work area clean and free of debris to prevent slips, trips, and falls.

- 6. Use proper lifting techniques: When lifting AAC blocks, use proper lifting techniques to prevent back injuries.

- 7. Follow manufacturer's instructions: Always follow the manufacturer's instructions for cutting, handling, and installing AAC blocks. These instructions will ensure that you are working safely and that the blocks are installed correctly.